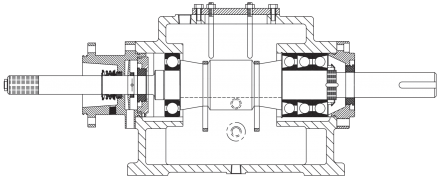

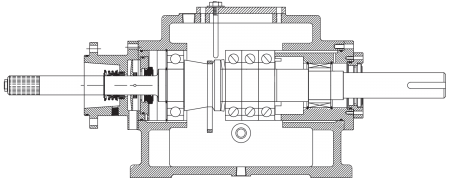

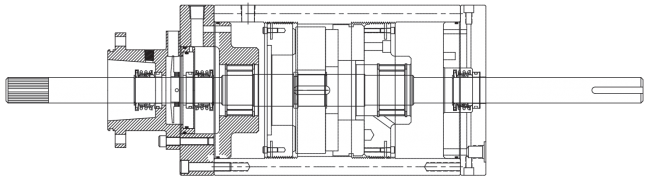

With a thrust load capable of up to 6000lbs the Standard Thrust Load Protector (TLP) is capable of handling the majority of injection applications. Designed from a heavy duty grey iron housing providing a rigid base the TLP is easily installed in the field and aligned by laser to the motor. The Stainless Steel designed wetted parts help prevent corrosion in harsh environments. The TLP design is standard with a type 2 bellows seal in monel construction. Additional cartridge and tandem API seals are available.